Strengthening Industrial Control Systems Cybersecurity: Learning from the Bosch Torque Wrench Breach

The recent cyber breach involving Bosch’s torque wrench serves as a sobering reminder of the critical importance of cybersecurity in manufacturing automation. The incident, where hackers exploited vulnerabilities in Bosch’s smart torque wrench to compromise sensitive data, underscores the urgent need for heightened vigilance and proactive measures to protect automated manufacturing systems from malicious attacks.

The Bosch Torque Wrench Breach:

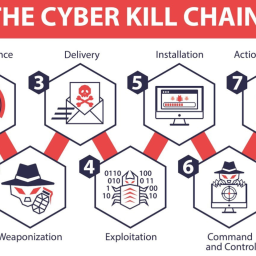

In the Bosch torque wrench breach, hackers exploited vulnerabilities in the device’s firmware, allowing them to gain unauthorized access to the wrench’s data and potentially manipulate its functionality. This breach not only raised concerns about the security of smart manufacturing tools but also highlighted the broader implications of cyber threats on industrial automation systems.

Cybersecurity Considerations:

The Bosch torque wrench breach emphasizes several critical cybersecurity considerations that manufacturers must address to safeguard their automation systems:

- Vulnerability Management:

Manufacturers must implement robust vulnerability management programs to identify, assess, and mitigate security vulnerabilities in their automation systems. Regular firmware updates, security patches, and proactive monitoring can help address potential weaknesses before they can be exploited by attackers.

- Secure Design and Development:

Secure-by-design principles should be integral to the design and development of automation systems. Manufacturers must prioritize security throughout the product lifecycle, from initial design to deployment, by implementing secure coding practices, conducting thorough security assessments, and integrating security controls into the manufacturing process.

- Data Encryption and Access Controls:

To protect sensitive data transmitted and stored within automation systems, manufacturers should employ robust encryption mechanisms and access controls. Data encryption helps prevent unauthorized access and ensures the confidentiality and integrity of critical information, while access controls limit user privileges and reduce the risk of unauthorized data manipulation.

- Third-Party Risk Management:

As manufacturing ecosystems become increasingly interconnected, manufacturers must assess and manage the cybersecurity risks posed by third-party vendors and suppliers. Implementing rigorous vendor security assessments, establishing clear contractual obligations, and conducting regular audits can help mitigate the risk of supply chain attacks and data breaches.

- Incident Response and Recovery:

Despite best efforts to prevent cyber-attacks, manufacturers must be prepared to respond swiftly and effectively in the event of a security incident. Developing comprehensive incident response plans, conducting regular tabletop exercises, and establishing partnerships with cybersecurity experts can help minimize the impact of breaches and facilitate timely recovery efforts.

Building Resilience Through Collaboration:

The Bosch torque wrench breach underscores the importance of collaboration among manufacturers, cybersecurity experts, and regulatory authorities to address the evolving threat landscape. Information sharing initiatives, industry standards development, and regulatory guidance can help foster a collective approach to cybersecurity that strengthens the resilience of manufacturing automation systems.

Final Thoughts:

The Bosch torque wrench breach serves as a wake-up call for manufacturers to prioritize cybersecurity in their automation initiatives. By addressing vulnerabilities, adopting secure design principles, implementing robust data encryption and access controls, managing third-party risks, and enhancing incident response capabilities, manufacturers can mitigate the risk of cyber-attacks and safeguard the integrity of their automation systems. As the manufacturing industry continues to embrace automation technologies, proactive cybersecurity measures are essential to protect against emerging threats and ensure the continued safety, reliability, and resilience of automated manufacturing processes.

https://www.topgallant-partners.com/security-blog/

0